Starch is the key carbohydrate in the human diet and the major storage structure in plants. The structure of the starch granule is surprisingly complex and has a number of hierarchical levels extending from the micron- to nano-scale.

These structural characteristics confirm considerable botanic variation, or differences between plants and this, in turn, causes considerable differences in the nutritional and industrial properties of different starches which form part of our diet.

This particularly manifests itself with differences in cooking properties. This study characterised this behaviour using simultaneous Rapid Visco Analysis (RVA) and small-angle neutron scattering [1].

Starch granules and pasting

Starch is deposited by plants in granules that show considerable botanical variation in shape and size distribution; generally granules range from 2 μm to 100 μm in dimension. Most of the granule is composed of essentially linear amylose and highly branched amylopectin. The ratio varies considerably between plant species.

The granules are further subdivided into growth ring structures, which alternate between amorphous and semi-crystalline structures.

The semi-crystalline rings have a repeating lamellar structure of periodicity 90 – 100 Å. This is easily observed using neutron scattering (small-angle neutron scattering – SANS) and x-ray scattering (small-angle X-ray scattering – SAXS) [2].

Other sub-structures such as superhelices and blocklets are thought to exist within the granule [3]. The pasting properties of starch are readily studied using the RVA unit, in which slurries of starch are subjected to a defined program of heating and cooling cycles which allows the cooking properties of starches to be reproducibly tested, for example, prior to sale.

This allows for grain quality control and can be used to assess viscosity changes during innovative processing techniques.

During a heating and cooling cycle in excess water, several changes in the RVA profile are observed. Firstly, a sufficient number of starch granules undergo such rapid swelling and partial amylose leaching, particularly following gelatinisation, that a rapid rise in viscosity is observed.

Under conditions of both heat and shear, the granules are partially disrupted and the leached amylose aligns, leading to a reduction in viscosity in most cases. On subsequent cooling, the hydrated polymers reassociate and the material undergoes a transition to a gel, which is observed as a ‘setback’ or increase in viscosity.

The corresponding changes in nanostructure however had not previously been characterised.

|

| Fig 1. Modified Rapid Visco Analyser assembly for SANS study. (B) indicates hollow impeller assembly through which neutrons pass. |

Simultaneous SANS and RVA

Neutrons have several key advantages for analysing the nanostructure of food systems, in particular their relatively high penetration through dense or concentrated samples and sample environments, as well as the ability to avoid beam damage. An industrial RVA unit, modified to allow a neutron beam to pass through it, is shown in Fig. 1.

This was then used on the Quokka SANS instrument at OPAL to collect simultaneous SANS and RVA data using a typical industrial test cycle of heating and cooling, while hydrated with deuterated water.

The cycle used in this study was 13 minutes long with the starch heated to 95°C over the course of 5 minutes, held at that temperature for 2 minutes and then subjected to a gradual cooling for the remainder of the profile.

|  |

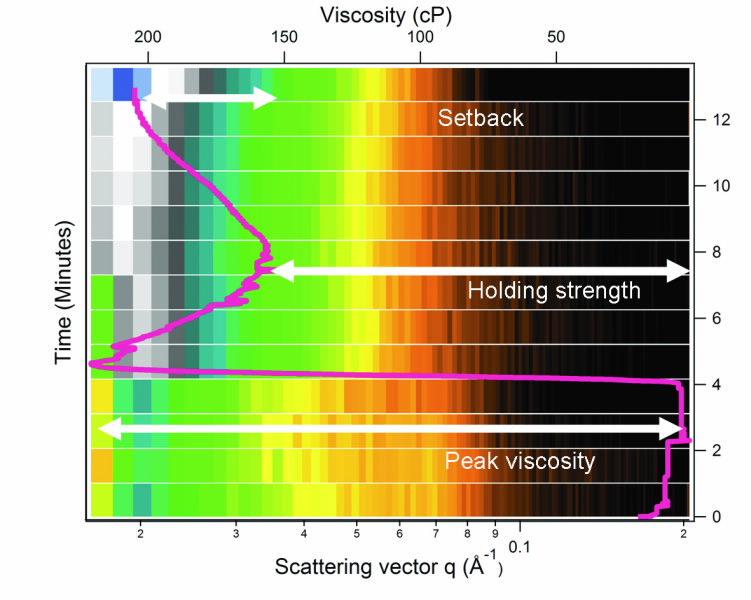

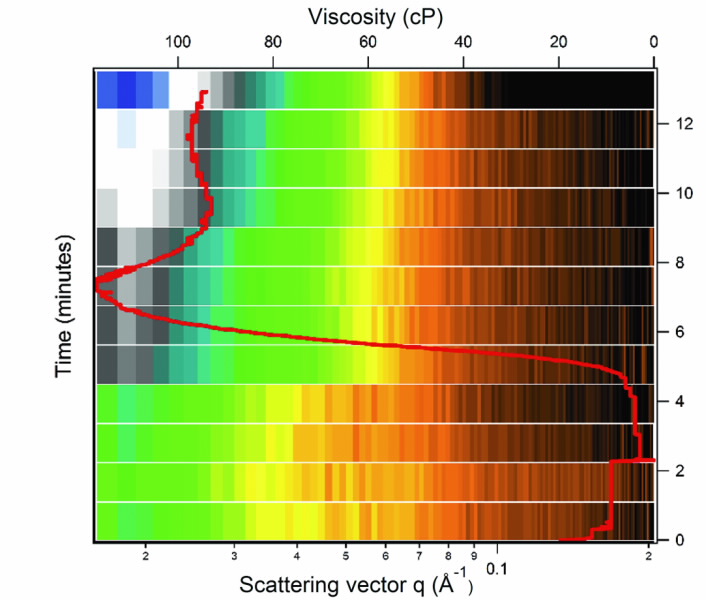

| Fig 2. (A) SANS data transposed with RVA visocity profiles as a function of time (A) Waixy Maize | Fig 2. (B) Maize; Black and white regions denote low and high intensity respectively (logarithmic scale) |

A fractal structure in the gels

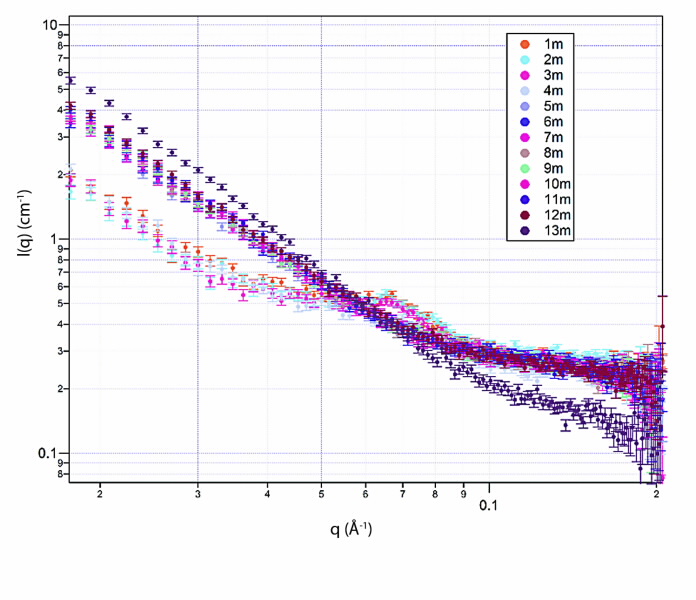

Fig. 2 shows simultaneous scattering and RVA profiles for two starches: the scattering at low-q values increases quite dramatically for both starches at the point at which the viscosity first starts to rise. This implies the formation of large scale structures and occurs after approximately 4 minutes. The scattering for waxy (amylopectin only) maize is shown in detail in Fig. 3.

Here, the periodic lamellar structure is destroyed after 4 minutes and replaced by power law scattering, in which the scattered intensity decays by some negative power with increasing q. This power law scattering shows variation through the remaining time of the experiment.

Power law behaviour in small-angle scattering experiments can indicate a number of structural possibilities; for example, regular shapes like cylinders, spheres or fractal structures. We were able to differentiate between these possibilities by placing the data on an absolute scale, a task easily achieved with SANS.

This clearly demonstrated that the gel structures had the form of fractals on the nanometre scale.

The data was analysed using the method of Teixeira [4]. In contrast to other structural interpretations in the literature, only this structural model is able to yield the correct volume fractions expected for the systems studied.

This analysis yielded some interesting variations between different botanical starch varieties. In particular, potato, tapioca and waxy maize form aggregates which are relatively large (~200 Å) compared with wheat and normal maize (~90 Å). There were also interesting differences in fractal or Hausdorff dimension.

This gives an indication of the morphological complexity of the system.

We deduced that tapioca and potato gels appear to have quite linear and relatively simple structure, whereas maize and wheat gels are much more complex and the aggregates quite polydisperse, while waxy maize is intermediate between the two groups. These nanoscale characteristics show excellent correlation with the macroscopic properties of the gels and invite further study.

The nanoscale parameters obtained from simultaneous SANS/RVA can be used to better understand structural transitions during starch gelation, across a wide variety of industrially relevant conditions.

|

| Fig 3. SANS data as a function of time during RVA measurement of waxy maize. The lamellar peak at ~0.065A is seen to disappear after 4 minutes, being replaced by decays that follow a power law with variable exponent between -2.24 to -2.32. |

Authors

James Doutch1, Mark Bason2, Ferdi Franceschini1, Kevin James2, Douglas Clowes1, Elliot P. Gilbert1

1ANSTO, 2Perten Instruments

References

- Doutch, J., Bason, M., Franceschini, F., James, K., Clowes, D., Gilbert, E. P. (2012). Structural changes during starch pasting using simultaneous Rapid Visco Analysis and small-angle neutron scattering. Carbohydrate Polymers, 88(3), 1061-1071.

- Blazek, J., & Gilbert, E. P. (2011). Application of small-angle X-ray and neutron scattering techniques to the characterisation of starch structure: A review. Carbohydrate Polymers, 85, 281–293.

- Perez, S, Bertoft, E, (2010), The molecular structures of starch components and their contribution to the architecture of starch granules: A comprehensive review, Starch, 62, 389-420.

- Teixeira, J, (1988) Small-Angle Scattering by Fractal Systems, Journal of Applied Crystallography, 21, 781-785.

Published: 24/07/2012