Plastic deformation of metals is inherently linked to the microstructure of materials, defining their mechanical properties and thermal behaviour. For the first time we have continuously followed the in situ evolution of embedded bulk grains of copper during the plastic deformation process of cold uniaxial compression.

Initially, coarse grains break up into subgrains and, depending on their initial alignment, rotate into their preferred orientation merging finally into a continuous texture. In contrast to previous investigations, the study shows not only the starting and final conditions but the full evolution of the microstructure.

|

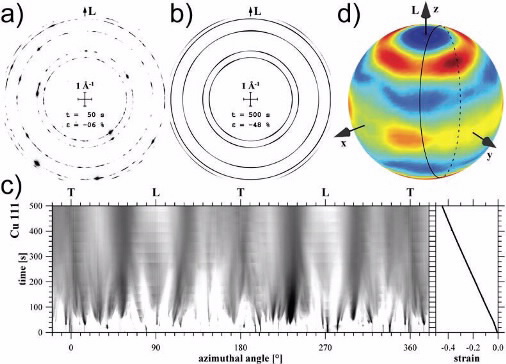

| Two-dimensional x-ray diffraction patterns (dark is high intensity) showing initially spotty Debye-Scherner rings from a small number of crystallites (a) evolving upon plastic deformation into continuous, but textured rings. (b). The intensities of the Cu-111 ring are plotted in dependence of azimuthal angle and time in (c) with longitudinal L and transverse direction T marked. A reconstructed 111 pole figure from a full texture measurement is given in (d) indicating schematically a line of measurement obtained from one Debye-Scherrer ring. |

Better materials through microstructure engineering

Making Synchrotron X-ray movies

Here we present in situ data of cold plastic deformation in coarse grained copper which gives detailed insight into the real-time evolution of the microstructure [1]. High-energy X-ray diffraction at the beamline ID15B of the European Synchrotron Radiation Facility was used to probe the bulk of the material.

The morphology of the Debye-Scherrer rings (Fig. 1a and 1b) is evaluated to obtain information about the grain statistics, crystallite perfection and grain orientation. For each time step, the Debye- Scherrer ring of a selected reflection (Fig. 1a and 1b) was cut at the 9 o’clock position and straightened into one line of Fig. 1c, the vertical axis in the dimension time.

Schematically, the final intensity distribution in Fig. 1c corresponds to the soliddotted circle on the surface of Fig. 1d. How texture forms It is interesting to follow how differently oriented grains merge into the final texture. If grains are arbitrarily oriented, for example with the (111) normal in the 70°-80° and 100°-110° regions of in Fig. 1c, they rotate away from the longitudinal direction into the preferred orientation of 56°.

A revolution for materials design

The presented mechanism and method allows one to track the evolution of embedded grains in detail giving valuable input for further theoretical modelling and the understanding of plastic deformation. Validated on the well understood system of Cu, we have recently applied this model to twinning induced plasticity steel [2]: a novel, high strength and ductile material being developed for the transportation and defence industries.

There are fundamentally different deformation mechanisms existent at high temperatures, like dynamic recrystallisation and dynamic recovery which compete with each other. We observed this for the first time in situ and in real time on a Zr alloy, a material relevant for the nuclear power industry [3]. In addition, we studied a Ti-Al based light metal alloy (at 1300°C with presented technique) that is being designed for aero-space applications.

The new method gives immediate feedback on what is happening in the material, which is considerably more efficient than the conventional processing, quenching, preparation and characterization techniques. Therefore, thermomechanic simulation shall routinely be done in a synchrotron or neutron beam in order to receive instantaneous feedback from the process.

Authors

Kun Yan 1,2, Klaus-Diester Liss 1, Ulf Garbe 1, John Daniels 3, Oliver Kirstein 1, Huijun Li 1,2, and Rian Dippenaar 2

1ANSTO, 2 University of Wollongong and 3 European Synchrotron

References

- Yan K., Liss K.-D., Garbe U., Daniels J., Kirstein O., Li H., Dippenaar R., “From single grains to texture”, Advanced Engineering Materials, 11/10 (2009), p. 771-773. doi:10.1002/adem.200900163.

- Yan K., Carr D.G., Callaghan M.D., Liss K-D., Li H, “Deformation mechanisms of twinning induced plasticity steels: In situ synchrotron characterization and modeling”, Scripta Materialia (2009), doi: 10.1016/j.scriptamat.2009.11.008.

- Liss K.-D., Garbe U., Li H., Schambron T., Almer J. D., Yan K, “In situ observation of dynamic recrystallization in the bulk of zirconium alloy”, Advanced Engineering Materials, 11/8 (2009), p. 637-640. doi:10.1002/adem.200900094.

- Liss K.-D., Schmoelzer T., Yan K., Reid M., Peel M., Dippenaar R., Clemens H., “In situ study of dynamic recrystallization and hot deformation behavior of a multi-phase titanium aluminide alloy", Journal of Applied Physics, 106, (2009), p. 113526/1-6 doi 10.1063/1.3266177

Published: 11/08/2009