ANSTO has collaborated on research investigating the possible synergistic effects of a new perovskite cathode material for a low-temperature solid-oxide fuel cell (LT-SOFC) that demonstrates outstanding and stable electrochemical performance below 500 °C.

A solid-oxide fuel cell (SOFC) converts the chemical energy in fuel into electricity directly by the oxidation of the fuel.

SOFCs have distinct advantages in that they are highly efficient, exhibit long-term stability, produce low emissions, and are relatively low cost.

The study, by Mengran (Aaron) Li and co-authors from the School of Chemical Engineering and the School of Chemistry and Molecular Biosciences at the University of Queensland, published recently in Nature Communications, showed that the co-doping of a promising cathode material, strontium cobalt oxide (SrCoO3-6) with niobium (Nb5+) and tantalum (Ta5+), led to improved performance.

The crystal structure of the new material was investigated using neutron powder diffraction on the ECHIDNA instrument at ANSTO’s Australian Centre for Neutron Scattering and X-ray powder diffraction, under the direction of Professor Vanessa Peterson.

Other collaborators included researchers from Shandong University and Nanjing Tech University in China.

Experiment and calculations indicated that synergistic effects occurred because of an optimised balance of oxygen vacancies, ionic mobility, and surface electron transfer.

This is believed to be one of the few studies to report on how co-doping a perovskite oxide with highly charged rare-earth or alkaline- earth elements catalyses the oxygen-reduction reaction (ORR) at the LT-SOFC cathode.

Historically, the performance of the cathode in LT SOFCs has been limited by the surface oxygen exchange kinetics of the ORR as well as the mobility of oxide ion in the bulk.1

New cathode materials, which form oxide ions by the reduction of oxygen, have been explored because the low operating temperature of SOFCs results in sluggish kinetics and limits the performance of the battery.

Because the crystal structure of perovskite oxides is not stable below 900 °C, they are doped with rare-earth or alkaline-earth elements.

In the study, strontium cobalt oxide was doped with niobium and tantalum to produce the cathode material SrCo0.8Nb0.1Ta 0-1O 3-δ (SCNT) and isostructural species.

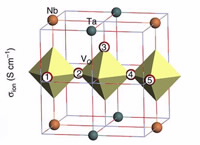

A cubic perovskite structure makes oxygen vacancies in the lattice migrate freely among equivalent oxygen sites.

|

| A schematic of the minimum energy migration pathway for an oxygen vacancy (VO) in SrCo0.75Nb0.125Ta0.125O3-δ, where dopants shown by coloured balls and Co along the pathway are within the octohedra. Other Co and Sr ions are omitted for clarity. The numbers 1–5 indicate the sequential positions of an oxygen vacancy along the diffusion pathway. |

To the best of their knowledge, the authors report the highest reduction of oxygen in a LT-SOFC.The transport properties of perovskite-type oxides are dependent mainly on the ϐ-site cations.

In SCNT, the niobium and tantalum have the same valence state and very similar ionic radii as the cobalt, and replace some of the cobalt ions.

The authors suggest the niobium and tantalum may be decreasing the energy barrier for oxygen migration, causing the neighbouring cobalt ions to become more active for charge transfer.

They attribute the high power density achieved using the pure SCNT cathode to outstanding ORR activity.

A range of other techniques were used in the synthesis of the material, structural characterisation, analysis of conductivity, characterisation of the ORR, and performance.

The SCNT cathode outperformed the other isostructural cathode compositions at and below 500 °C and surpassed the target of 500 mW cm-2 for SOFCs, suggesting the possibility of operation even below 450°C.

1 http://dx.doi.org/10.1016/S0167-2738(98)00179-9

Published: 24/01/2017