12:00noon

Lucinda Eeson is arranging with Rey Ico of the OPAL maintenance team to set up vibration analysis equipment on one of the reactor cooling water pumps. This equipment is part of a plant condition monitoring program to measure and record data to identify an impending plant failure before it occurs.

|

| Rey Ico of OPAL maintenance team sets up to a vibration analysis test on a reactor cooling water pump |

As an integral part of the OPAL Engineering team, Lucinda Eeson, a Process Engineer, is responsible for an array of reactor sub-systems.

These include conventional ventilation and containment ventilation, containment referring to the sealed environment within the reactor building.

OPAL process Engineer Lucinda Eeson “We have a ventilation system that removes heat energy thus keeping the temperature in containment constant.”

Her role involves working alongside ANSTO maintenance and contractor teams to ensure all her systems are working at their designed performance and reliability.

“We do this whilst sustaining all safety prerequisites and meeting regulatory and licensing requirements.” Eeson explained that “unlike conventional plants, in-built engineered redundancy applies to all nuclear critical process systems throughout the OPAL reactor.

Should one of these systems fail or be under-performing a standby or back-up unit will automatically start up”.“Being an engineer at OPAL offers an opportunity to help others in a multitude of ways due to the widespread functions and importance of the reactor to Australia.”

1:00pm

Tina Cignarella is processing a request for a document change from engineering and maintenance and recording it in the online documentation system.The Technical Support Group provides documentation, auditing, regulatory compliance, training and information technology expertise for Reactor Operations. Any change to a controlled document or drawing or the creation of a new controlled document is very carefully managed to ensure people have quick and easy access to the documentation and can review a summary of changes.

Tina Cignarella of the Technical Support group There are 1395 approved controlled documents in the integrated business management system.

An example of a change might be a modification to an operating manual for a system, a technical change within an instruction or a structural change to a drawing.

“Being part of a team that has such a big impact on the operation of OPAL is very rewarding” said Admin Support Officer Tina Cignarella.

The Technical Support Group on the Configuration Management team manages the integrated business management system and the management system auditing program for the Nuclear Operations cluster.

2:00pm

Joanne Lackenby is meeting with a system engineer to discuss a modification to a component of the reactor.

As the OPAL licensing officer, Joanne Lackenby is familiar with the ARPANSA Act, regulations and OPAL’s license to operate.

“Part of my job is ensuring we meet all of our requirements, which includes regulatory reporting.

“It involves making sure that everyone in reactor operations is following the processes that align with the regulations.

OPAL Licensing Officer Joanne Lackenby “I spend quite a bit of time talking to people if they want to make changes to the reactor and assist them with the safety categorisation.”

The safety categorisation determines the level of safety review and approval required before the change can be made.

We go well beyond basics to ensure there are no cliff edges.”An important concept in keeping the reactor operating safely is defence-in-depth, which requires several levels of protection, including successive barriers preventing the release of radioactive material to the environment.

With a PhD in geotechnical engineering and her role as the president of Women in Nuclear Australia, Lackenby also works to change public perceptions of nuclear.

3:00pm

Ross Finlay is having a telephone conversation with CERCA, the French company that supplies uranium target plates used for the production of Molybdenum-99 and OPAL fuel.

Fuel Specialist Ross Finlay has responsibility for overseeing the fabrication, procurement, and transportation of the low enriched uranium fuel used in OPAL and collaborates on ensuring its performance.

He also looks after the uranium target plates that produce Molybdenum-99, the precursor of the important diagnostic radiopharmaceutical, Technetium -99m.

“Lots of people at ANSTO look at fuel from different angles but I would be consulted if there was an issue, for example, if someone noticed an imperfection on the fuel plate.”

Fuel Specialist Ross Finlay There have been no performance issues with the fuel as ANSTO has used the same fuel design since 2008, which is provided by CERCA in France.

Finlay travels to Argentina and France for inspections of each fuel assembly and uranium target plate that are the source of nuclear medicine.

Every single fuel assembly spends five to six months in the reactor core before it is depleted and changed.

“Part of the success of the OPAL reactor is the way it is operated and maintained. People around the world are astounded by the performance we achieve.”

4:00pm

The Nuclear Analysis team has been on the phone with the reactor operator in the main control room providing new calibration constants for power level estimations in the reactor. The information is based on an analysis of thermal balance in the reactor and provides the means to calculate real power.

|

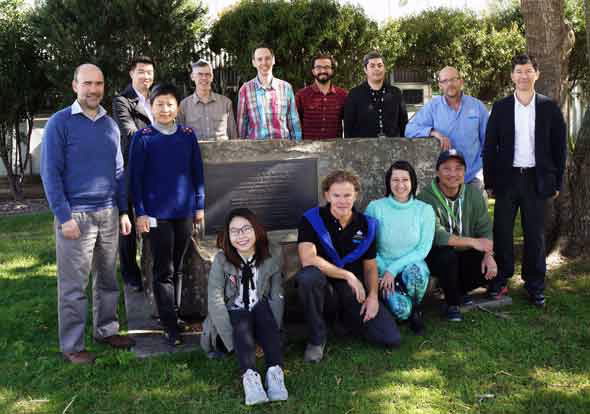

| Nuclear Analysis section staff (back row left to right) George Braoudakis, Mark Ho, John Osborn, Rodney Hall, Robert Mardus-Hall, Andrew Pastrello, David Wassink, Tunay Ersez (front row left to right) Huayou Wu, Da-in 'Rebecca' Choi, Fernando Esposto, Racquel Lovelace, Weijian Lu. Not shown: Guan Yeoh |

Published: 06/09/2016As a member of the nuclear analysis section (NAS), formerly known as reactor physics, Weijian Lu provides support to reactor operations in terms of the physics, engineering analysis, neutron transport, and thermo-hydraulics.

Nuclear analyst Weijian Lu Using computational tools, we look at physical effects, the chain reaction in the core and criticality, fuel burn-up, fuel management, movement of the elements in the core, tracking the performance and integrity of the core, control rod movement, and shielding,” said Lu.

The safety analysis work done by the team forms a key component of the Safety Analysis Report, a 20 chapter-plus document that details meeting compliances for an operating license to be issued by the nuclear regulator in Australia, ARPANSA.

We construct highly useful three dimensional models of the reactor using powerful tools, in neutron transport and computational fluid dynamics (CFD).”

The NAS team also provides the neutronic and thermo-hydraulic calculations for the cold neutron source, the technology that provides cold neutrons to a suite of scientific instruments.

The cold neutron source cools neutrons in the reactor from room temperature down to -250 C, to decrease their energy.

Our work matters because our estimates of the reactor under different scenarios really have consequence for safety and performance.”