ANSTO researchers have joined the thousands of experts from 35 countries working worldwide to resolve technological challenges relating to a world’s fusion energy collaboration, the International Thermonuclear Experimental Reactor (ITER) in France by assisting with neutron diffraction studies on the materials used in the superconducting cables.

Measurements on the Kowari residual stress diffractometer in collaboration with researchers from the Japan Atomic Energy Agency (JAEA) were used to provide direct evidence of microdamage in the superconducting cables due to thermo-electro-magnetic cycling and established a link to a possible cause of deterioration.

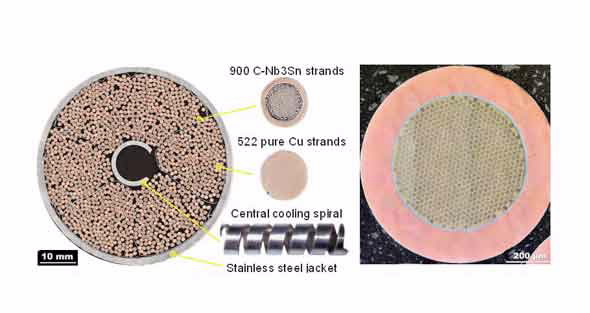

ANSTO research focused on the phase, texture and residual stress characteristics of the Cable-in-Conduit-Conductors (CICC) made mainly of niobium-tin (Nb3Sn, the superconducting media) and copper (Cu).

|

| (Left) Structure and structural elements of CICC TF cable (Right) Structure of a single Nb3Sn superconducting strand (diameter 820 µm) showing Nb3Sn filaments of 2.8 µm in diameter, copper matrix and Nb 8 µm thick barrier in blue. |

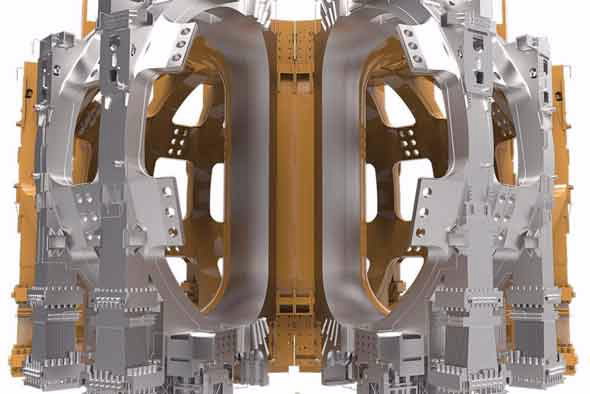

Cables that become superconducting at 4°Kelvin (K) or -269°Celsius (C) are to crate magnetic field trap to initiate, shape and control the plasma inside the vacuum vessel of the reactor. Superconductors are used in the reactor because they consume less power and are cheaper to operate than conventional magnets. They carry higher currents and produce stronger magnetic fields.

“The state-of-the-art superconducting cables are a core component of the project and their performance is a central issue,” said Instrument Scientist Vladimir Luzin.

The two major superconducting cables for ITER are complex structures comprising the toroidal field and central solenoids. Both cable types have the CICC design which comprises a central spiral of bundled superconducting strands made of niobium-tin (Nb3Sn) in copper matrix and enclosed within a structural steel jacket.

During operation of the ITER central solenoid conductors at 4.3° K, the transverse electromagnetic forces, known as Lorentz forces, are generated by a current of 40 kiloamperes (kA) under a magnetic field of 13.0 Tesla (T) causing somewhat distributed loads at the strand to strand contacts along their length. The Lorentz forces are generated by the toroidal field conductors by a current of 68 kA under 11.8 T.

“The Lorentz forces cause a distribution of the loads along their length, generating complex microstress fields” explained Luzin.

Additionally, thermally-generated strains are also produced when cables are cooled from the production temperature of 650°C to room temperature and then to the cryogenic operation temperature.

“Moreover, the differential thermal contraction between materials of the strands produces strains and stresses on microscopic scale.”

The long term performance of the CICCs in cable prototypes was also known to show degradation with an increasing number of current/magnetic cycles. In the earliest tests, the CICC failed after 1,000 cycles, far short of the quality standard of 60,000 cycles. “Strain in the strands affects the critical current,” said Luzin.

“The degradation of superconducting properties by thermo-electro-magnetic cycling is caused by strains and stresses through the accumulation of microdamage,” explained Luzin.

|

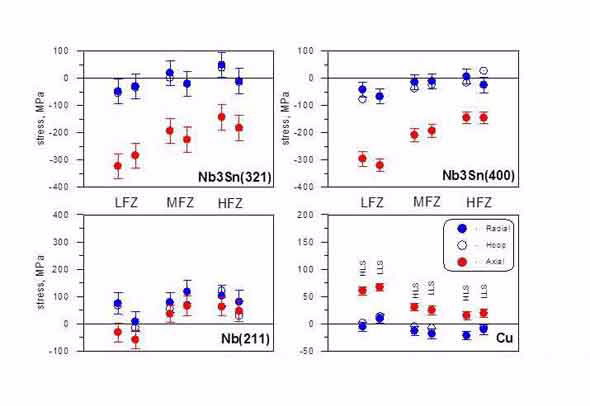

| Neutron stress analysis for TF cable for three phases: Nb3Sn (10%), Nb (2%) and Cu (88%) performed for three cable magnetic field conditions (LFZ=low field, MFZ=medium field, HFZ=high field) |

Neutron diffraction is an ideal method of analysing the stress state of the cables because of their ability to penetrate materials and measure phases separately.”

It is believed to be the first time that the residual stress of all phases of the composite material, (88% Cu, 10% Nb3Sn and 2% Nb) cycled under different magnetic field conditions, was measured.

Luzin said the results of the measurements provide a solid experimental basis for further advancing the interpretation of the details of micromechanical damage mechanism and a dataset for validation of micromechanical modelling predicting mechanical behaviour and performance of the cables under operational conditions.

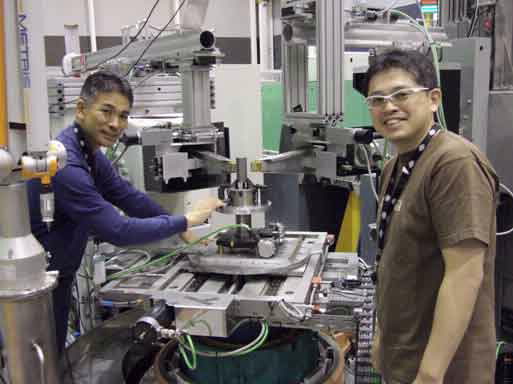

ANSTO made its neutron beam facilities available to the Japanese following the shutdown of national neutron facilities, J-PARC and JRR-3 after the Tohuku earthquake in 2011. Japan is one of the seven members of ITER, who are collaborating over 35 years to build and operate the demonstration fusion reactor in France.

|

| Koichi Akita (left) and Hiroshi Suzuki (right) from the Japan Atomic Energy Agency preparing for the experiment on the Kowari instrument |

Japan is the main producer of the CICCs in the ITER project. The Japanese collaborators who work at the Japan Proton Accelerator Research Complex (J-PARC) and the Japan Atomic Energy Agency (JRR-3) focused their research on the thermo-elastic response and anisotropy of Cu and Nb3Sn at cryogenic temperatures.

Currently the most expensive ever the multibillion dollar scientific project of the fusion energy reactor has the potential to produce carbon-free clean power by fusing hydrogen nuclei (2H and 3H) to form helium in high temperature plasma. Temperatures in the reactor’s core reach up to 200 million degrees Celsius.

Ten thousand tonnes of magnets, with a combined stored magnetic energy of 51 gigajoules will produce the magnetic fields of 11.8 Tesla that initiate, confine shape and control the plasma. More than 200 kilometres of superconducting cables have been manufactured for ITER.

ITER is the first device to test the integrated technologies, materials and physics necessary for the commercial production and industrial use of fusion based electricity.

Published: 27/04/2016