|

| Dr Anna Paradowska with the KOWARI Instrument. |

Hardchrome Engineering, a manufacturing company, applies an advanced metal-deposition technology - Laser Cladding - to the refurbishment of steam power turbine blades used in power generators.

Check out a video below of some of the state-of-the-art laser cladding being done now at Hardchrome's Melbourne-based facility.

Dr Anna Paradowska from ANSTO's Bragg Institute is helping Hardchrome Engineering to understand the residual-stress distribution in these complex critical components.

The first non-destructive measurements of the residual-stress distribution in the turbine blades have just been performed on our neutron strain scanner, KOWARI.

The experimental data from KOWARI will assist Hardchrome Engineering to deliver improved, safe, and cost-effective technology that will increase the operational efficiency and lower the maintenance costs of Australian power plants.

Mehdi Soodi from Hardchrome Engineering and Anna Paradowska worked together to set up the turbine blade on the KOWARI Strain Scanner at ANSTO.

Residual stress diffractometry can be used to reveal residual stresses in thermo-mechanically processed metals (e.g. rails and pipelines), different welded components, in bulk components like spray forming and in thick coatings like thermal spray and laser cladding.

|

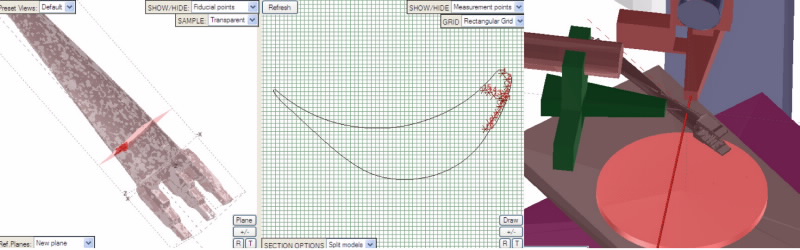

| KOWARI Strain Scanner at ANSTO, which is equipped with a SSCANSS virtual instrument to help optimize the experimental study of complex shapes. |

Here is a video of laser Cladding currently being done at Hardchrome's Melbourne-based facility.

Published: 12/12/2013