The fabrication of graphene is a highly dynamic field in materials science. Processes to produce porous graphene have especially attracted increasing attention for their potential applications in sensing, energy storage, membrane separation, biological sequencing, composite materials and nano-electronics.

|

| Atomic structure of graphene Photo credit: Argonne National Laboratory. |

ANSTO’s highly skilled Radiation Technology team has helped a Victorian group of innovative researchers develop a new, highly efficient method of preparing porous and reduced graphene oxide.

|

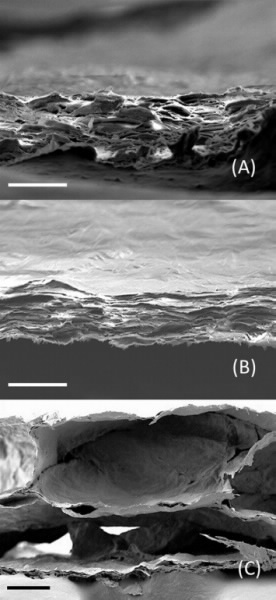

| (A) SEM images; pristine GO BP (scale bar is 10 μm), (B) 500 kGy γ-ray irradiated GO BP (scale bar is 10 μm) and (C) rGo BP and (scale bar is 50 μm). A Supra 55 VP SEM was used for imaging (working distance 5 mm at accelerating voltage of 5 keV). The thickness of the hydrazine reduced GO BP was increased nearly 19-fold compared to that of the original GO BP, while that of the 500 kGy irradiated sample was found to remain essentially unchanged. |

Deakin University's Ludovic Dumee works in environmental sustainability through the development of novel nano-materials for water desalination, industrial waste purification and gas separation. This part of his research focuses on developing new routes to use carbon nanotubes and graphene as growth substrates for the formation of micro-porous networks.

His new one-step, catalyst-free, high penetration and through-put technique offers for the first time a significant advantage over previously reported graphene oxide (GO) solution reduction mechanisms.

The new technique, using gamma irradiation, maintains the naturally densely packed morphology of GO bucky-papers without causing the dramatic exfoliation of the graphene layers caused by chemically reduced routes.

Utilising the high precision irradiation facility at ANSTO to carefully vary the amount of irradiation, the team was able to find a dose which increased the surface porosity to 33.5% - the largest GO surface porosity reported to date.

| ANSTO LifeSciences contacts: Justin Davies, Connie Banos |

Dumee, L., Feng, C., He, L., Yi, Z., Velleman, L., She, F., Peng, Z., Gao, W., Banos, C., Davies, J. B., Huynh, C., Hawkins, S., Duke, M. C., Gray, S., Hodgson, P. D., Kong, L. Single step preparation of meso-porous and reduced graphene oxide by gamma-ray irradiation in gaseous phase. Carbon 2014 70 313-318 http://dx.doi.org/10.1016/j.carbon.2013.12.094

Published: 10/06/2014