Enjoying a day at the beach in summer provides a good opportunity to observe how a granular material behaves.

Just look down, sift some grains of sand through your hand, build a sand castle or watch the sand flow as the surf comes in. Beach sand is a good example of this distinct form of matter that can demonstrate the properties of a solid, liquid and gas, depending on the circumstances.

Granular materials display an astounding range of complex behaviour that is still being studied. Unravelling the rich and often unexpected behaviour of granular matter points to clear limitations of conventional continuum-based approaches, in particular elasticity theory or simple hydrodynamics.1

A better understanding of the mechanics in granular materials has significant industrial importance for the pharmaceutical industry, agriculture, and energy production.

Recent research at the Australian Nuclear Science and Technology Organisation (ANSTO) involving the operational residual-stress diffractometer Kowari and the newly-commissioned neutron imaging instrument Dingo within the Bragg Institute has provided a window into how these unique forms of matter behave under stress.

|

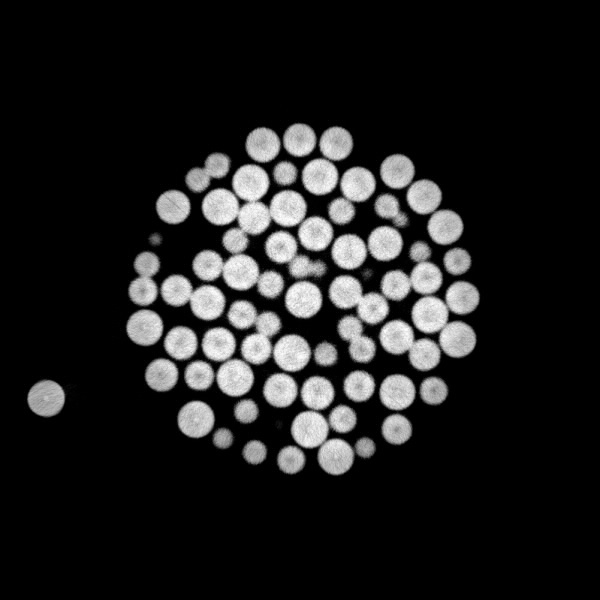

| Neutron imaging on Dingo instrument provides a 3D tomographical slice of individual particles within a die and an external marker. The image can be optimised by computation to accurately locate each particle. |

Scientists from the University of Newcastle, the Bragg Institute and the European Spallation Source have just published a research paper2 in Physical Review that is the first to use data from this newly commissioned instrument.

Chris Wensrich and Eric Kisi of the University of Newcastle, Vladimir Luzin and Ulf Garbe of the Bragg Institute and Oliver Kirstein of the ESS probed the stress state within a steel ball bearing assembly subject to significant external pressure.

The assembly consisted of 549 steel ball bearings in a specially designed cylindrical die under an applied axial load of 85MPa (60kN of force applied over a 30mm diameter cross section).

“Through a combination of neutron imaging on Dingo and strain mapping on the Kowari residual stress diffractometer we have demonstrated that it is possible to uncover detailed information on the conditions experienced by individual particles within three dimensional assemblies,” said Wensrich.

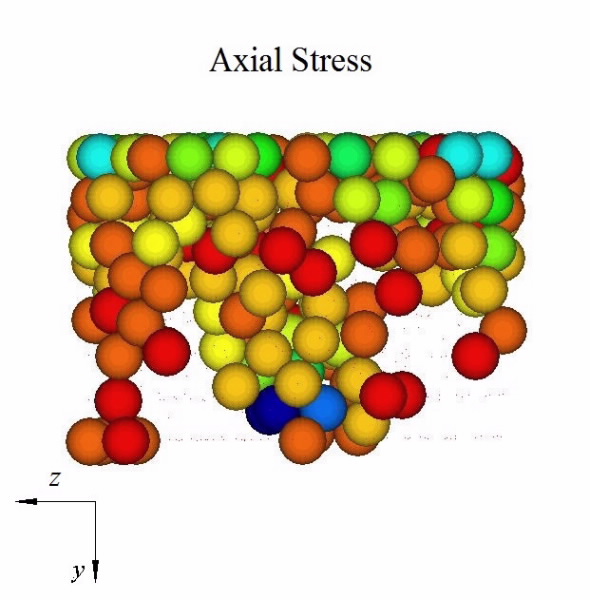

Measurements from the nuclear imaging instruments provided the first direct three-dimensional observations of force chains in granular systems. Force chains typically form a network that extends throughout an entire assembly, rapidly adapting and changing in response to deformation and are considered an inherent feature of granular matter.

“Force chains are networks of particles within an assembly that form a skeleton that supports the majority of the internal load. These linked arrays of particles carry relatively large loads while other particles may not see any load at all.”

The scientists commenced the study with a preliminary investigation involving the mapping of strain within a ball bearing assembly using just the Kowari instrument. This preliminary work showed a high level of inhomogeneity (significant spatial variations in the conditions experienced within the assembly) and gave some indications of the presence of force chains within the system.

However, it was soon realised that without detailed knowledge of the locations of individual balls, this type of measurement would suffer from a number of issues that would dramatically increase the uncertainty. The commissioning of Dingo provided the opportunity to perform a much more sophisticated measurement.

“Using Dingo, it was possible to precisely locate each individual ball within the bed. After carrying out a careful alignment process, we could then drive to each ball and measure the full three dimensional strain state using Kowari” said Wensrich.

|  |

| Three-dimensional image depicts how individual particles experience stress and the presence of a force chain. |

By applying this process to each of the 549 balls within the die, it was possible to characterise the full discrete triaxial stress state of the entire assembly. The resulting information has provided one of the most detailed views of the inner workings of a granular material.

“A dominant feature of the measurement was the widespread inhomogeneity within the bed” explained Wensrich. “Force chains can clearly be observed”.

The authors point out that, at the moment, the approach applies to only high stress states. They also suggest that future improvements in precision may allow the calculation of the force network from a measurement of this kind.

Dingo was funded as part of the Australian Governments Super-Science Initiative, which designated $1.1 billion for critical areas of scientific endeavour.

Dingo and Kowari are among a suite of state-of-the art neutron beam instruments in operation or being commissioned at ANSTO operated by the Bragg Institute. The neutrons are generated by the Open Pool Australian Lightwater Reactor (OPAL), Australian’s only nuclear reactor and one of the world’s best multi-purpose research reactors.

The Australian Radiation Protection and Nuclear Safety Agency gave approval to commence the use and commercial operations of the Dingo neutron radiography/tomography/imaging station in November 2014.

The main applications of Dingo are non-destructive, non-invasive studies of the movement of hydrogenous materials like water or oil in metal or ceramic objects or devices, the flow of lubricants and fuels in engines, oil and water flow in rocks related to oil and natural gas extraction, water damage in aerospace components, uptake of water in the roots of plants, and the investigation of valuable cultural and archaeological artefacts and rare and uniquely preserved fossils.

Kowari measurements of residual stress and strains are non-destructive and apply to nearly all crystalline materials. They provide sub-surface information often not obtainable by any other technique. The main applications are in engineering to find stresses in welds and coatings and provide evidence of corrosion cracking and fatigue in structural components and load bearing parts. It is also used to investigate new materials such as shape memory alloys. It is also useful to study the interior of older materials, such as metal and ceramic artefacts and geological specimens.

1 "Does the granular matter?" Heinrich M. Jaeger*†, Troy Shinbrot‡, and Paul B. Umbanhowar§ Proceedings of the National Academy of Sciences 97, 12959-12960 (2000)

2 "Force chains in monodisperse spherical particle assemblies: Three-dimensional measurements using neutrons", C. M. Wensrich, E. H. Kisi, V. Luzin, U. Garbe, O. Kirstein, A. L. Smith and J. F. Zhang, Phys. Rev. E 90, 042203 (2014).

Published: 06/02/2015