Braving -30°C arctic conditions in Maddison, Wisconsin, USA, three senior scientists from ANSTO's Institute for Environmental Research Drs Klaus Wilcken, Zeljko Pastuovic and David Fink, and chief accelerator technician David Garton, conducted factory acceptance tests on ANSTO’s newly purchased 6 million volt particle accelerator.

Fortunately, the inside of the National Electrostatics Corporation factory was 18°C, perfect conditions for running high tech electronics and keeping drinks and operators cool. On entering the NEC factory for the first time the ANSTO team was led down a labyrinth of corridors and taken to the depths of the original factory where some of the largest electrostatic accelerators were made.

| |

|

They were taken to a new wing which is also the largest in the factory, built to accommodate the growing demand for accelerators worldwide. As they approached the accelerator for the first time it appeared many times larger than was imagined on paper. However, they were somewhat reassured to see that it was so big, as it allayed any fear they felt that the new building 53 extension may have been over-designed.

ANSTO’s new accelerator is the largest NEC accelerator to be built in decades. In fact, it is so big that it could not be fully assembled within their new factory.

The intense factory testing program focussed on the ability and performance of the accelerator to produce high quality ion beams for Accelerator Mass Spectrometry (AMS) and Ion Beam Analysis (IBA).The ANSTO team was given full control of the accelerator which was pushed to the limit to measure performance against a detailed specification.

|

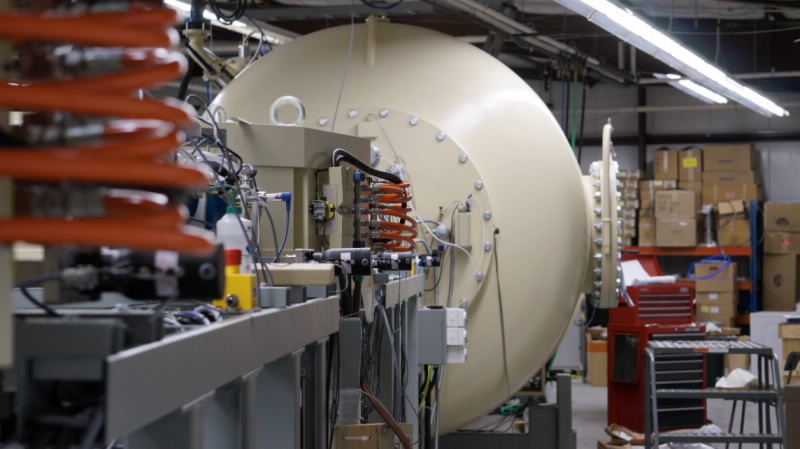

| The 6 million volt accelerator high voltage generator is inside of a tank that is 3 metres in diameter and about 10 metres long. |

Their professionalism and knowledge in accelerator science surprised the NEC engineers who praised their commitment, rating it amongst the best they had experienced during a testing program. The tests ran smoothly but several issues arose related to beam transmission. It was decided that they were simply development issues rather than fundamental design faults.

NEC has assured this issue will be resolved prior to shipping the accelerator to ANSTO in a few months’ time. The ANSTO team are confident that they will receive a high quality machine that will meet expectations.

The NEC staff were very hospitable, patient and incredibly generous with their time considering the ANSTO team’s somewhat pedantic but thorough ways.

After an eventful trip, where even the car rides felt like sitting in a freezer, the team returned to ANSTO with their new accelerator not too far behind them. In the hands of these experienced scientists this impressive instrument is sure to be the envy of research labs around the world for many years to come.

|

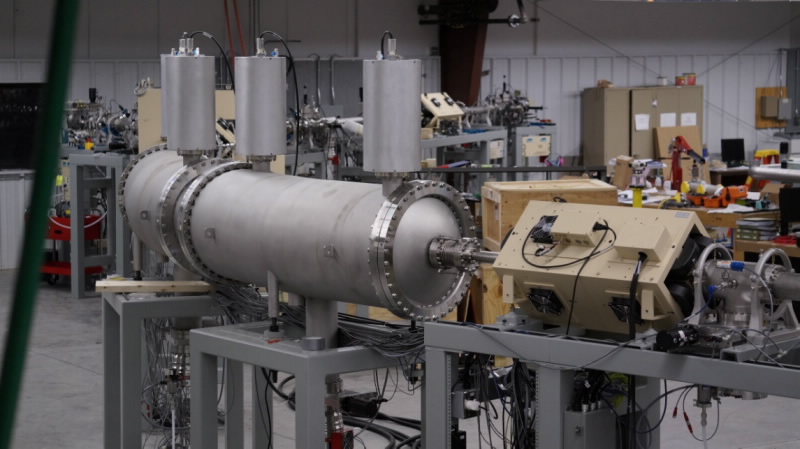

| The electrostatic analyser (ESA) on the AMS beam line. The ESA acts like a filter on the ion beam to separate different isotopes. |