The editors of a special issue of the Materials Research Society MRS Bulletin have suggested that future research trends must utilise complementarity—applying multiple techniques using different quantum beams for a more efficient and effective characterisation of materials.

|

“While development may be approaching technical and optical limits, combining methods can provide answers,” said Prof Klaus-Dieter Liss, a senior researcher and instrument scientist at ANSTO, who co-edited the recently-released issue on advances and trends in synchrotron radiation research in materials science.

“Because ANSTO operates the 3 GeV Australian Synchrotron, a major user facility for research using high intensity X-rays, as well as much of Australia’s other major science infrastructure, it can provide researchers with the option of combining approaches at one organisation,” said Liss.

A multitude of different scattering, diffraction and imaging techniques can be applied to probe advanced materials.

For example, undertaking investigations using X-rays and neutrons on the same samples can produce comprehensive structural information about complex materials and how they behave under exotic conditions.

Light scattering devices, synchrotron X-rays and neutron beam instruments can elucidate the dynamic nature of materials at the atomic scale.

Neutron scattering and muon spin techniques are useful for studies of magnetic properties.

Positron annihilation spectroscopy and X-ray Compton scattering can be used to measure electron momentum density.

Combining Ion channelling techniques with X-ray diffraction topography can reveal structural defects in a crystal.

The crystallographic orientation of a polycrystalline sample, or texture, can be determined by electron backscatter diffraction, X-ray diffraction and neutron diffraction. All methods have distinct advantages, such as high local resolution or bulk penetration and ensemble averaging.

|

| The Australian Synchotron |

Both neutron and synchrotron radiation are very important for local atomic strain/stress analysis in mechanical engineering.

The authors pointed out that the availability of sample environments, high pressure apparatus, chemical reactors and thermo-mechanical processors allows investigators to analyse materials in extreme environments.

Data analysis has been expedited by the development of automated, smart and comprehensive computing power.

An introduction by Liss and co-editor Kai Chen of China’s Xi’an Jiaotong University also highlights the tremendous advances in the sources, instrumentation and applications of synchrotron radiation to characterise materials. The topics are explored in depth by supporting articles from multiple invited contributors.

New facilities, including the Australian Synchrotron, have optical systems with the ability to produce images and diffractograms (pictorial images of diffractions rings and spots) with angular resolution (the ability to distinguish small details) as good as the instrument's theoretical limit, deliver coherent or “in step” photon beams and operate at ultra-short time scales.

Methodologies using X-rays are based on the key overlapping concepts of diffraction, spectroscopy and imaging with a subset of specialised techniques, including absorption spectroscopy, inelastic scattering, surface scattering and deep bulk diffraction.

White beam Laue diffraction, when it is combined with micro and nanometre-sized beams, can be used to determine the orientation of a crystalline microstructure locally and reproduce orientation maps.

“With respect to electron diffraction methods, X-rays are advantageous because their high intrinsic angular resolution can identify local strain and derivative components of strain in materials,” said Liss.

Diffraction, spectroscopy and imaging can be combined and interwoven in techniques such as diffraction-contrast imaging in topographic methods, which led to the novel method of dark field X-ray microscopy.

The highlights challenging experiments on samples, such as those producing a low number of diffraction spots, which can now be mapped by using magnifying optics in the diffracted X-ray beam path. The resolving contrasts that are available through X-ray topography can reveal crystal distortions, grain boundaries and the orientations of sub-grains.

Various X-ray energy ranges have relevance for specific applications.

|

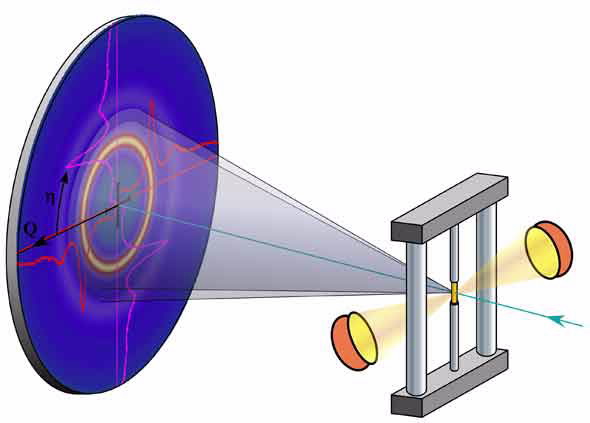

| Typical 2D high-energy x-ray diffraction setup: a small beam arriving from the right is scattered by the specimen into Debye–Scherrer cones, which are mapped as diffraction rings on a flat-panel detector. Superimposed to the 2D detector image are four radial sections of the intensity. The specimen is in a mechanical load frame, heated by halogen lamps; however, a vast variety of sample environments can be designed, such as in an in operando battery cell, and reaction chambers. |

High energy X-rays with energies above 80 KeV are able to penetrate into bulk materials, such as exceeding a depth of one centimetre in steel.

X-rays can be tuned to atomic spectroscopic levels, such as those used in the absorption spectroscopic method to investigate specific chemical ionisation states and local atomic environment in complex materials, including electrochemical applications and substances under high pressure.

Two and three dimensional detectors, which can simultaneously record diffraction rings and positions, provide advanced texture analysis and mapping of microstructure.

|

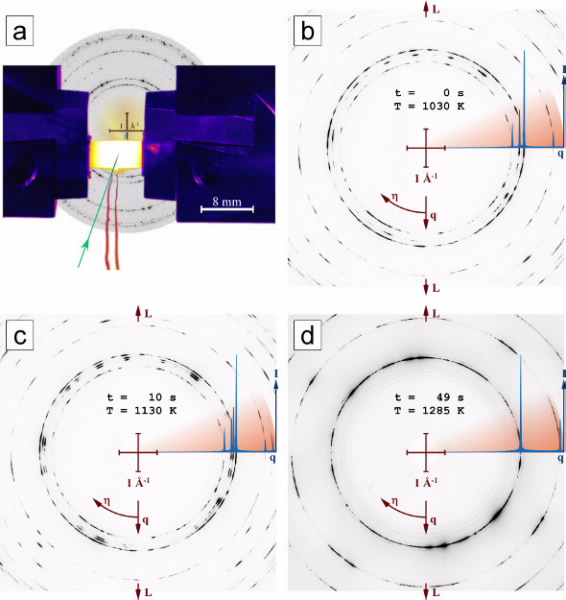

| 2D in situ data acquisition from a materials oscilloscope. (a) False-color photograph of a glowing titanium aluminide-based alloy specimen (cylinder, 8 mmlength and 4 mm diameter) between the jaws of a thermomechanical processor. The thermocouple is shown by the two red lines at the bottom. A sketched incoming beam and a diffraction pattern in the background were added to the illustration. 30 diffraction patterns from a zirconium alloy under heating in (b) α phase and (c) ( α + β ) phase, and(d) during hot plastic compressive flow in the β phase. |

At ANSTO, Liss has developed the concept of the materials oscilloscope, in which two-dimensional diffraction rings are captured in real time; creating a movie while a specimen undergoes thermo-mechanical treatment.

Characteristic traces in diffractograms help distinguish various deformational and annealing processes, such as grain coarsening, refinement, subgrain formation, grain rotation, slip, twinning, dynamic recovery and recrystallisation.

It is reported that high energy X-ray investigations with time-resolved in situ and in operando experiments are important for the analysis of cathode synthesis, the loading cycle, charge and discharge processes and studies of buried layers in energy storage materials.

“With the refinements and advances we have seen in synchrotron techniques, complemented by neutron scattering, the future is very bright indeed for materials science research and industrial applications,’ said Liss.

Link to publication: http://dx.doi.org/10.1557/mrs.2016.112

Link to a MRS webinar on the topic: http://www.prolibraries.com/mrs/?select=session&sessionID=6218

Published: 30/06/2016