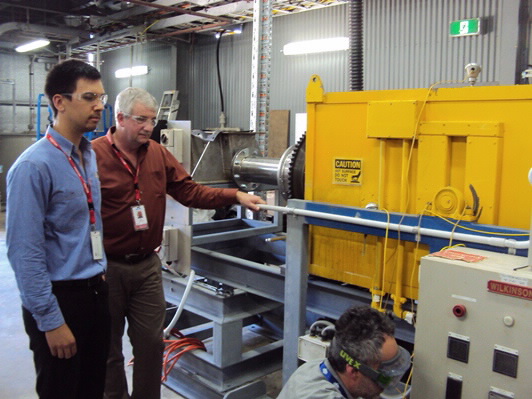

Roy Gordon (left, Metallurgist, Peak) and Rocky Smith (right, Chief Operating Officer, Peak) by the ANSTO pilot plant Rotary Kiln.

ANSTO Minerals has worked with Peak Resources Limited (ASX: PEK) on the development and optimisation of Ngaulla Rare Earth Oxide Project in Tanzania.

As a result of the successful optimisation testwork, Peak Resources has commissioned ANSTO Minerals to operate the pilot plant to validate the optimised “Alkali Roast” process flowsheet that has been selected by Peak for the Bankable Feasibility Study. The study is expected to be completed by early 2017.

The pilot plant will process approximately two tonnes of high grade concentrate (>40% REO) from the beneficiation pilot plant and produced a cerium depleted filtrate, high in neodymium and praseodymium which is suitable for direct feeding to the SX. Operation of the pilot plant has already commenced.

Please read below an extract from Peak’s ASX Announcement in February 2016 below.

New Recovery Flowsheet developed to reduce Operating and Capital Costs

Peak Resources Limited (Peak; ASX Code: PEK) is pleased to announce the completion of technical development programs that have resulted in a simplified leach recovery flowsheet.

The new flowsheet has been successfully trialled on the high grade concentrate produced by the beneficiation pilot plant and is a significant improvement over the flowsheet developed during the Preliminary Feasibility Study (PFS).

Summary

Peak has completed extensive test work on the high grade mineral concentrate and a new flowsheet has been developed that achieves the following outcomes:

- Reduced plant capital cost through a smaller plant of modular design

- Lower operating costs due to reduced reagent consumption

- Focus on the extraction and recovery of the high value magnetic metals praseodymium and neodymium

- Significant reduction in the extraction of low value cerium, further reducing reagent costs in the leach recovery circuit and also the size of the downstream separation plant

- Minimises the extraction of deleterious elements thereby simplifying the purification process.

This process has been developed in house by Peak’s metallurgical team and optimised at Nagrom in Western Australia and ANSTO Minerals (ANSTO) in NSW. ANSTO has been selected for piloting the new flowsheet and construction of the pilot plant is nearing completion.

Peak’s Managing Director Darren Townsend commented “The development and implementation of the improved leach recovery flowsheet builds on the strengths of the beneficiation process recently piloted by Peak. We look forward to updating the market on the operating cost and capital costs of the Ngualla Project in the first half of 2016.”

View the ASX Announcement released by Peak Resources: New recovery flowsheet developed to reduce operating and capital costs

Or visit the Peak Resources website for more details.

ANSTO Minerals contact:

Adrian Manis

Pilot Plant Manager

[email protected]