ANSTO's Structural Integrity and Material Research Unit is actively engaged with the modelling and simulation of material responses to high strain-rate and high temperature phenomena. Analysis of high velocity impacts has shown that material behaviour demonstrates sensitivity to both strain rate and the adiabatic heating of the material.

This often leads to localised deformations which cannot be predicted using conventional analysis techniques. e.g. shear banding, adiabatic thermal softening and pressure induced phase transformations amongst others. Therefore we are now developing this high strain-rate method for use in a wide variety of fields including the defence sector.

|

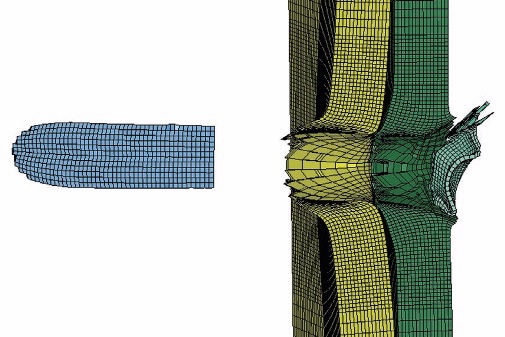

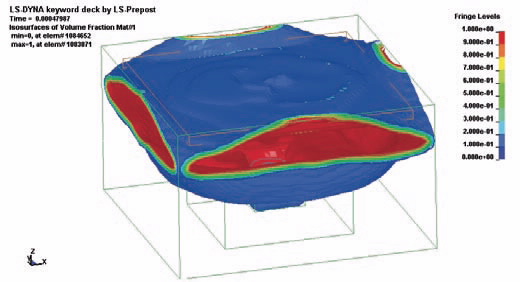

| Figure 1: Simulating a 7.62mm Armour piercing round impacting two 6 mm Armox560T plates. |

Material response to large dynamic loads

The analysis of the material response is reliant on a firm understanding of the complexities of dynamic loading and the associated physical responses that govern the material’s deformation. Examples of high strain rate/high temperature events are seen in metal stamping and tooling in the manufacturing industry, collision evaluation in the automotive industry, bird strike in the aerospace industry and ballistic and blast protection in the defence sector.

These highly transient events occur in tens or hundreds of microseconds and require the use of non linear continuum mechanics. New Finite Element Analysis codes were commissioned for this work, namely LS-DYNA [1] which is the fastest explicit Finite Element solver available. The new analysis procedure developed has built capabilities within ANSTO and for its partners that were previously unavailable.

The solution was made possible through new material models, contact algorithms, new element formulation (SPH, Smoothed Particle Hydrodynamics and ALE, Arbitrary Lagrangian- Eulerian). Further work is envisioned in the area of meshless simulations which negates the effect of element distortion in Lagrangian based analysis.

Having amassed a great degree of nuclear expertise in the areas of material identification, testing and the development of material modelling techniques, ANSTO is an important core participant of the Defence Materials Technology Centre (DMTC). Established in 2008, the centre is a collaborative engagement of industry, universities, defence organisations and other national research facilities. Here, we report about the research project with the DMTC, including partnerships with the University of Wollongong and the University of Melbourne.

Preparing tests

Our research has built capabilities in the area of high strain-rate analysis, using both phenomenological and mechanistic approaches to describe material behaviour. This will be used in the future as we will bridge the gap between atomistic and macroscopic modelling. High strain-rate research is being carried out by a number of manufacturing, automotive and defence institutions around the globe.

The DMTC has also deemed this research essential for the development of indigenous armoured structures. High strain-rate testing will be carried out in conjunction with our project partners in the first quarter of 2010. A concerted effort has been made to identify the required material tests to accurately define the necessary constitutive models. The testing will likely include Split- Hopkinson pressure bar tests, high and low-strain rate furnace tensile tests to account for adiabatic heating and pressure testing for calibration of the model.

Transmission electron microscope and scanning electron microscope analysis techniques will likely be used in the mechanistic constitutive model derivation. Amongst the most widely used constitutive models are those by Johnson-Cook [2] and Zerilli-Armstrong [3]. The research may also lead to new user defined analysis models for inclusion in the Finite Element Analysis.

Validating data for models

Figure 1 shows one step in the 3D axissymmetric Lagrangian mesh simulation of a 7.62 mm armour piercing round impacting two 6 mm Armox560T plates. Armox560T is manufactured by Swedish steel maker SSAB and is claimed to be the “world’s toughest protection plate” [4]. It is a low alloy quenched and tempered steel with a yield stress of 1300 MPa and a reported tensile strength of 1600-1900 MPa.

This steel has been evaluated by the Norwegian defence force and published literature [5] provided the necessary data and results to benchmark our numerical result. Some of the metrics used in the evaluation of these models include depth of penetration, residual bullet velocity, hole diameters, and other components.

The ANSTO model uses the Johnson-Cook plasticity [2] relation and the Cockcroft-Latham [6] fracture model. A penalty based element contact algorithm with an erosion criteria that deletes highly distorted elements is utilised, thus alleviating premature termination of the simulation due to floating point errors or stress singularities. This models is better in predicting the projectile response than the published simulations [5] on which it is based. The brass bullet jacket has been stripped and the tip of the steel core has been eroded.

The residual velocity, (Vr) of this simulation was 198 m/s compared to the measured Vr of 200 m/s and the original papers [5] simulation of 286 m/s. The physical features of the model are validated against published results [5]. Figure 2 combines a high-speed photograph of the ballistic experiment together with a postexperiment metallographic cross-section of the impact area. The rotation of the bullet, the erosion on the bullet tip and the cratering of the entry hole all provide good validation data for the models produced.

|  |

| Figure 2: Ballistic test of a 7.62mm Armour piercing around impacting two 6 mm Armox560 T plates. | |

The development of these models is essential in harnessing scientific techniques for the engineering design process. The capabilities developed have, for the first time, allowed the industry partner to anticipate material failure in a virtual environment with minimal need for expensive and often complicated ballistic tests. The development of the next generation armour will employ these models in lieu of the current ad hoc design strategies.

Another development in our modelling capability is the evaluation of Fluid Structure Interaction (FSI) models which couple the fluid motion to the mechanical response of the material. These have seen use in sloshing analysis of fluid containers, fluid motion analysis and the development of airborne blast models.

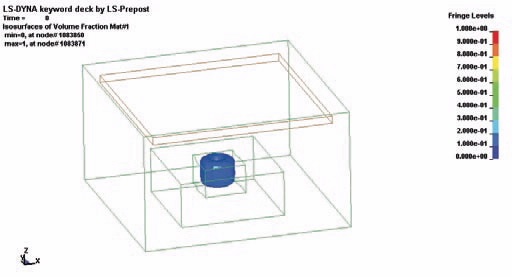

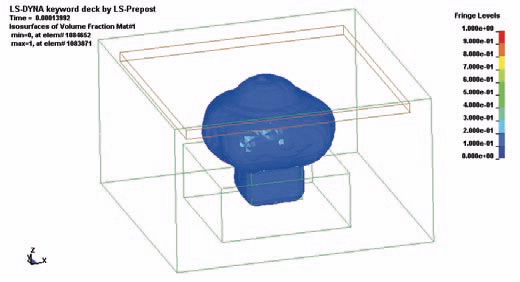

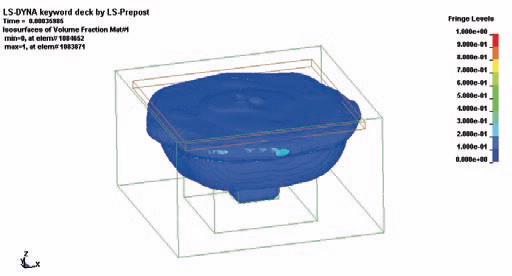

Figure 3 shows the results of a coupled FSI simulation of a 6 kg mine blast on a 590 kg steel plate. The expanding gas cloud moves through a static mesh (Euler mesh) where material transfer between elements occurs. Momentum transport formulation is used in this simulation. This simplified model is significant as it accounts for the concentrating effects of soil craters and the inclusion of an equation of state characterises the fluid behaviour of the blast gases and the surrounding air. This model was built after two previous iterations using the CONWEP [7] blast method and this formed part of our continuing contribution to the DMTC’s collaborative effort.

The next iteration of the blast model will include a soil formulation to capture the large effects entrapment have on the imparted kinetic energy. This has been identified as an urgent analysis tool to combat the increased use of improvised explosive devices against Australian Defence Force (ADF) personnel. ANSTO’s effort in both the ballistic and blast simulation provides measurable benefits to the ADF and secondly to Australian Industry.

Our work has also been publicised through the International Symposium on Ballistics [8] with the aim of furthering our knowledge and demonstrating our capabilities.

|

|

|

|

| Figure 3: SEQ Figure \* ARABIC 3. Coupled Fluid Structure Interaction simulation of a 6kg mine blast on a 590kg steel plate. |

Authors

Michael Saleh and Lyndon Edwards

ANSTO

References

- Hallquist, J.O “LS-DYNA Keyword User’s Manual, version 971, Volumes 1 and 2, (2007) Livermore Software Technology Corporation, Livermore, CA.

- Johnson, G R; Cook, W, H, Proceedings from the 7th International Symposium on Ballistics, The Netherlands, (1983) pp. 541–547.

- Zerilli, F.J; Armstrong, R.W, Journal of Applied Mechanics Vol.61 Issue 5 (1987) pp1816-1825.

- HYPERLINK “http://www.ssab.com/en/Products-and-solutions/Armox/” http://www.ssab.com/en/Products-and-solutions/Armox/

- Børvik, T; Dey, S; Clausen, A.H, International Journal of Impact Engineering, Vol 36 (2009) pp948-964.

- Cockcroft, M.G; Latham D.J., J. Inst. Metals 96 (1968), pp. 33–39.

- TM5-855-1, “Fundamentals of Protective Design for Conventional Weapons” U.S. Department of the Army, Washington DC, 1986.

- Saleh, M; Edwards, L “Evaluation of a hydrocode in modelling NATO threats against steel armour” Proceedings of the 25th International Symposium on Ballistics 2010