Since their discovery last century, neutrons have been established as an excellent tool for use in magnetism research, which has a wide range of technological applications such as increasing the storage capacity of computer hard drives.

The neutron’s high magnetic moment and its large penetration depth enables scientists to perform magnetometry at atomic to mesoscopic length-scales in bulk and thin-film materials.

This study focused on the chemical order in a thin film of FePt3, which features a completely new way of creating functional magnetic interfaces. Using neutron reflectometry and neutron diffraction, we can elucidate important physics of the magnetic interactions in our system.

This could potentially have technological applications for the information and communication technology industry.

Thin film and multilayer magnetism

The area of thin magnetic films and multilayers offers a wide range of technological applications. A prime example is the discovery of the giant magnetoresistance (GMR) effect in layered magnetic systems for which P. Gruenberg and A. Fert were awarded the Nobel Prize in 2007.

Only discovered in 1986, GMR-based devices are already implemented as read heads in most hard-disc drives of computers. This has resulted in increased data storage density in these devices.

The magnetic exchange-bias phenomenon is another extremely useful tool in magnetic recording which is being implemented in modern hard-disc drives. Temperature dependent exchange-bias results from pinning a ferromagnetic magnetisation in one layer by direct contact with a second, antiferromagnetic layer [1].

In detail, if we cool a ferromagnetic/antiferromagnetic layered system in a magnetic field, the ferromagnetic orientation will be “glued” to the magnetic-field orientation and it will be harder to reverse.

Although this has been known for over 50 years and heavily used in many technological applications, there is still no complete understanding of the effect and therefore preparing and producing exchange-bias devices can have diverse results.

The strength of the effect is directly related to the quality of the contact between the ferromagnet and antiferromagnet. In thin layered films, this contact quality can be described in terms of compatibility of the two materials and quality of the contact area, or “the right glue for the right surface”.

Neutrons play an essential role in the search for the “right glue”, as they provide information on magnetic structures with high accuracy. The ability to perform direction resolved depth dependent investigations as a function of temperature is unmatched by any complementary magnetometry technique.

|

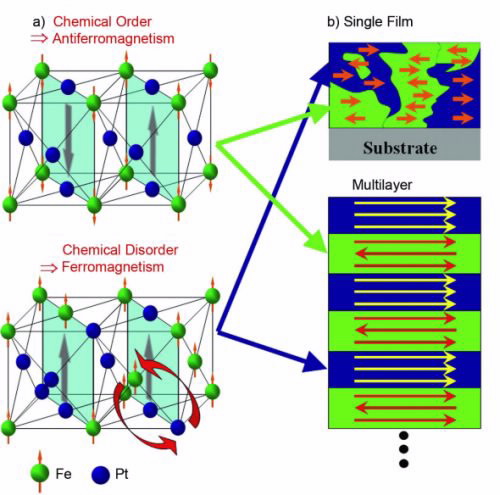

Schematic view of chemical order and magnetism in FePI3. a) Depending on the growth temperature, either antiferromagnetic or ferromagnetic phases evolve in the system. b) Top: Intermediate growth temperatures lead to a separation in ferromagnetic and antiferromagnetic domains. |

FePt3: Order makes the difference

We have adopted a new approach to create a magnetically modulated exchange-bias system with perfect structural interfaces in mono-material FePt3 thin films [2]. The material FePt3 can exhibit both ferromagnetic and antiferromagnetic properties, only depending on the chemical ordering, i.e. the regular arrangement of the Fe and Pt atoms in the lattice [3].

In perfect order, with Fe only occupying corners of a face-centred cubic lattice (Fig. 1a.), the system develops antiferromagnetism below a temperature called the Néel temperature. If a random distribution of Fe and Pt is present, the system shows ferromagnetic properties (Fig. 1a).

It turned out that this chemical ordering can easily be controlled by the temperature under which the thin film is grown, below 900 K for disordered FePt3 and above 900 K for high degrees of order.

Therefore we can choose whichever property, ferromagnetic or antiferromagnetic, is preferred and as such we can grow a system representing one material with two different magnetic phases, determined by the degree of ordering.

By modulating the growth temperature successive layers of ordered and disordered FePt3 in an alternating fashion can be grown with each interface composed of ferromagnetic/antiferromagnetic transition (see Fig. 1b).

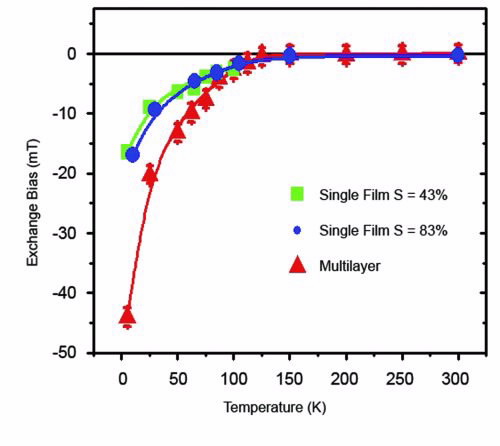

Standard magnetometry experiments prove that our created materials indeed show the desired exchangebias effect, identifiable by a temperature-dependent horizontal shift of the magnetic hysteresis loop by an amount called the exchange-bias field (Fig. 2).

|

| Exchange bias measured as a function of temperature for the thin film and multilayer samples. |

|

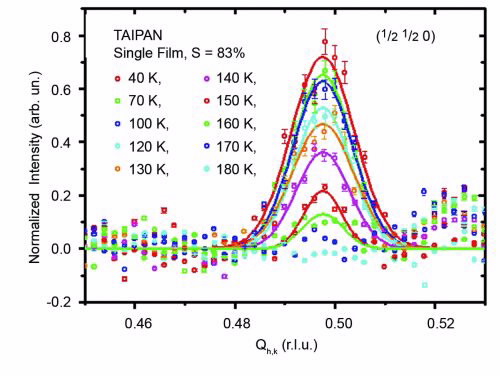

| High-angle neutron diffraction along the (1/2 1/2 0) direction as a function of temperature. The half- order peak is a direct indication of the antiferromagnetism along this direction. |

Magnetism and neutron diffraction

In order to distinguish the two magnetic phases and gain insight into the characteristics of our artificial mono-material magnetic multilayer, a combination of neutron techniques is used. No other probe is sensitive to structural and magnetic compositions even far below the surface without damaging the sample.

High-angle neutron diffraction resolves atomic positions and atomic magnetic moments and their respective orientations. Similar to atomic structures in a confined lattice, magnetic moments and their periodicities give rise to observable Bragg diffraction peaks. Antiferromagnetic peaks can easily be identified, as they show a periodicity of twice the structural lattice, which gives rise to a ‘half-order’ peak.

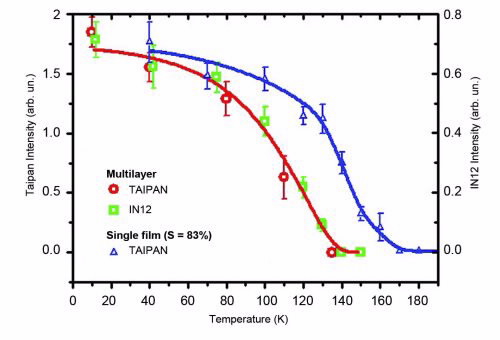

The crystallographic direction under which this half-order peak occurs represents the ordering direction of the magnetic moments, which can successively be traced in temperature until close to the magnetic ordering temperature (Fig. 3 and 4).

In the case of our artificial FePt3 magnetic multilayer, we observe a strong, temperature-dependent half-order diffraction peak (see Fig. 3), which identifies the same antiferromagnetic order as drawn schematically in Fig. 1a.

The temperature, below which the peak is observed, is characteristic for the antiferromagnetic transition, which in turn defines the temperature of the exchange-bias onset. In general, the same principle applies for ferromagnetic orientations.

However, due to the superposition with intensities from structural diffraction peaks, these can be harder to separate.

|

| Temperature dependence of the integrated antiferromagnetic peak intensity as a comparison of sinle films FePt3 and the artificially modulated multilayer structure. Different symbols indicate the instrument on which the data was recorded. The magnetic transition temperature of the multilayer is lower, but the antiferromagnetic ordering is comparable. |

Magnetism and neutron reflectometry

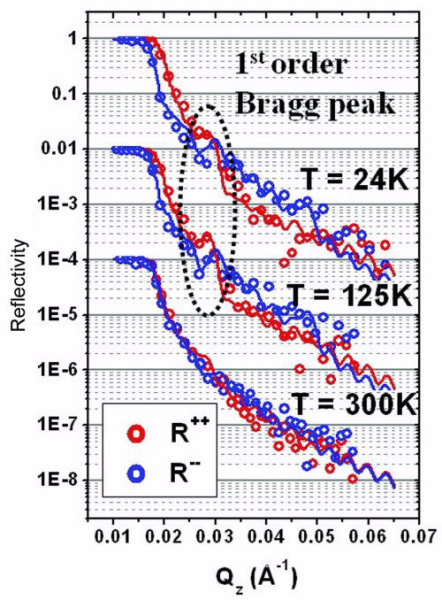

The depth-dependent multilayered structure of the samples has been investigated using the polarised neutron reflectometry technique. Neutrons of preferential spin polarisation (“spin up” and “spin down”) are illuminated onto the sample under shallow incident angles and reflected from the surface.

After the reflection process, the neutron carries important information of the materials composition, structure and magnetisation. The technique is especially sensitive to interfaces and structures on a nanometre length-scale.

Due to the mono-compositional property of the film, we only expect a contrast from layers of different magnetisations. The difference between two-spin polarisations is directly related to the average magnetic moment, while the first-order Bragg peak indicates the thickness of the ferromagnetic/antiferromagnetic layers and their individual magnetisation (Fig. 5).

By fitting the reflectometry data, a detailed depth-resolved model of the ferromagnetic regions can be obtained. The temperature evolution of this model provides essential information for the interpretation of the observed exchange-bias signal.

In summary, the combination of polarised neutron reflectometry and neutron diffraction allows us to elucidate the important physics of the magnetic interactions in our exchange-bias systems. We succeeded in creating an artificial magnetic modulation without changing material constituents and exchange bias was observed for single and multilayered films.

Furthermore, this example highlights the unique possibility of studying exchange-bias phenomena in systems without structural roughness or incommensurate material. A detailed study of the observed exchange-bias effect in view of existing theories will bring new insights into the physics of exchange bias to extend existing models.

|

| Polarised neutron reflectometry (symbols) and fits (lines) of the FePt3 multilayer. The splitting between the two channels is proportional to the magnetisation and the first-order Bragg peak indicates the ferromagnetic/ antiferromagnetic modulation periodicly. |

Authors

Thomas Saerbeck1, Frank Klose2, Anton Stampfl2, Sergey Danilkin2, Mohana Yethiraj3,

Dieter Lott4, Andreas Schreyer4, Gary Mankey5, Zhihong Lu5, Patrick LeClair5 and

Wolfgang Schmidt6

1University of Western Australia and ANSTO, 2ANSTO, 3Alta, Utah, USA, 4GKSS, Geesthacht,

Germany, 5University of Alabama, USA, 6Forschungszentrum Jülich, Germany

References

- Stamps, R. L. (2000). Mechanisms for exchange bias. Journal of Physics D: Applied Physics, 33(23), R247.

- Saerbeck, T., Klose, F., Lott, D., Mankey, G. J., Lu, Z., LeClair, P. R., et al. (2010). Artificially modulated chemical order in thin films: A different approach to create ferro/antiferromagnetic interfaces. Physical Review B, 82(13), 134409.

- Bacon, G. E., & Crangle, J. (1963). Chemical and magnetic order in platinumrich Pt+Fe alloys. Proceedings of the Royal Society of London A: Mathematical, Physical & Engineering Sciences, 272(1350), 272-387.

Published: 16/02/2011