Researchers from the University of Queensland and Monash University in collaboration with ANSTO scientists have clarified how behaviour of tailorable nanoscale emulsions (TNEs) interact with their targets is directed by the interfacial structure. The study was recently published in Soft Matter.

The collaboration reported that the ‘top down’ approach imparts a remarkable flexibility on the number and range of surface modifications for drug delivery, molecular imaging, engineered vaccines and industrial uses.

They describe a unique model system that allows the controlled assembly of multifunctional nanoparticles that can potentially be delivered in living persons.

The investigation, led by Dr Frank Sainsbury from the Australian Institute for Bioengineering and Nanotechnology at the University of Queensland, provided a detailed analysis of the building blocks of the TNE, a preliminary verification of the assembly mechanism and determination of the molecular characteristics in the water phase.

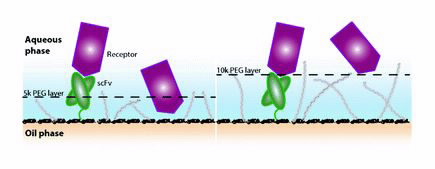

Because a TNE surface is tuneable in a sequential stepwise fashion, it offers great flexibility to control the interfacial characteristics of the oil-in-water emulsion containing nano-sized oil droplets.

|

The nano-emulsion acts as soft nano-carrier and gives you a high surface area to use for delivery of a drug or other product,” said co-author Dr Stephen Holt (left), who collaborated on the research with Dr Stefania Piantavigna (below right) at the Australian Centre for Neutron Scattering.

|

Piantavigna, who is a post-doctoral researcher fellow from Monash University, University of Queensland and ANSTO, has specific expertise on the characterisation and optimisation of nano-emulsions for cell targeting purposes.

X-ray reflectometry at the Australian Centre for Neutron Scattering was a technique used to determine the thickness of the engineered molecules an air-liquid interface (that mirrors the oil-water interface).

A typical nano-emulsion contains oil, water and an emulsifier, a molecule that has a hydrophobic (non-polar) end and a hydrophilic end.

The method is based on the interfacial mixing of biosurfactant protein and closely-related biosurfactant peptide.

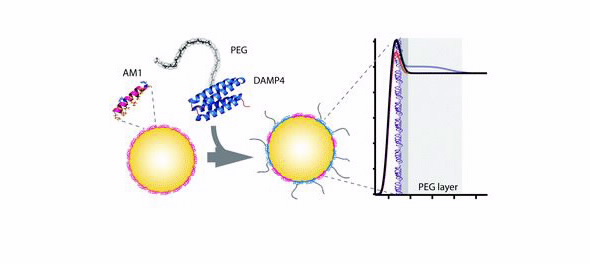

The nano- emulsions in this study were stabilised with a designer protein anchoring surfactant, DAMP4 and functionalised with the polymer polyethylene glycol (PEG).

PEG is used to improve pharmacokinetics.

The DAMP4 is comprised of four amphiphilic surface active peptides (AM1s), which are used to stabilise nanoscale oil-water emulsions.

“We tried to understand how molecules are presented at the oil-water interface and determine the best way of loading things up,” said Holt.

Function is linked to structure in self-assembling macromolecules.

“It is possible to attach other building blocks by conjugating them directly to the PEG or the DAMP4,” said Holt.

The PEG layer was vital in reducing non-specific interactions at the surface.

The interfacial interactions in three systems with different molecular weights, DAMP4, 5kDa- PEG-DAMP4 and 10kDa-PEG-DAMP 4 were compared.

The 10kDa-PEG-DAMP 4 model proved to best in restricting the interaction to the desired molecule.

The longer PEG keeps the non- specific interaction away from the surface,” said Holt.

|

“Even if you had another application in mind, such as the adsorption of an unwanted chemical, you could link that directly to this interface.”

http://pubs.rsc.org/en/content/articlehtml/2017/sm/c7sm01614j